Facilities List

Mean Machine Inc is all about high precision machine tools.

We offer a wide variety of specialized CNC machining services from CNC Milling and Turning to an unmatched Swiss screw machining capability. All backed with excellent Quality Assurance and the other services you'd expect from a professional machine shop.

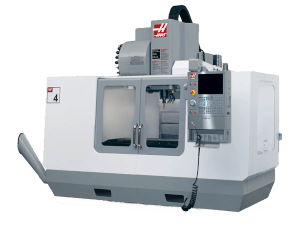

CNC Milling

We have a wide range of CNC milling machine tools that allows us to handle any job.

In addition to our Vertical Machining facilities, our precision milling machines include the latest in horizontal milling technology with our Matsuura precision milling machine.

Matsuura H.Plus-300

CNC Mill offering a pallet size of 300 x 300 mm (11.81 x 11.81 in.) with a working envelope of Ø530 x H760 mm (Ø20.86 x H29.92 in.). Tool storage is a 90-tool system with 2 pallets. Spindle speed is 15000 rpm.

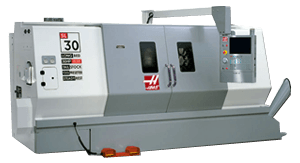

CNC Turning

We have a range of CNC lathes capable of handling up to 4" bar.

Our largest CNC lathe can turn a 30 inch diameter part.

We offer precision turning in metal and plastic.

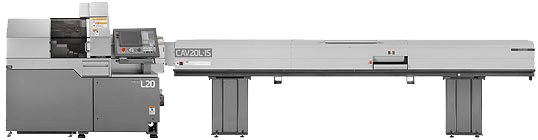

Swiss Screw Machining

Unrivaled in the area is our Swiss machining capability.

We are the go to Swiss screw machine shop.

We have 4 Swiss screw machines for your precision screw machining work.

Additional Equipment and Software

Quality Assurance

We provided excellent Quality Assurance through our MICRO HITE 3D CMM by TESA, which is operated in a climate controlled environment.

Complimentary Equipment

We have an extensive range of complementary equipment.

- TIG welding

- Drum and Vibratory tumblers

- CNC cold saw

- up to 14”

- Vertical bandsaw

- up to 17” cut

- Chop saw

- up to 14” cut

LOCATION

Mean Machine Inc.

2791 Wood Street

Oakland, CA 94607

CONTACT INFO

©2020 Mean Machine Shop - all rights reserved | Privacy Policy